1967 Lamborghini Miura – Chassis # 3051

This Lamborghini P400 (production # 36) has been languishing in its current disassembled state for almost 40 years. Affectionately named ‘Topo’ by its longtime owners, the car is currently undergoing a total restoration in the Team CJ Workshops.

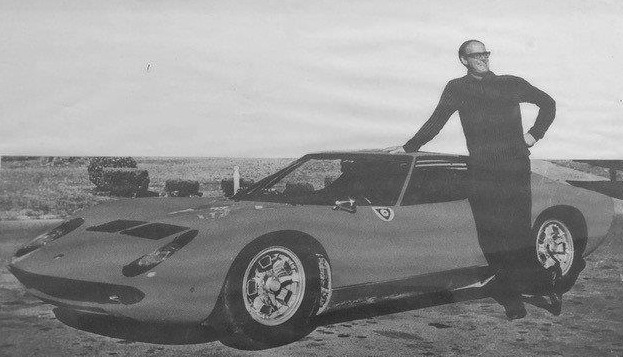

Purchased new by renowned gentleman racer, oil heir and sportscar personality Toly Arutunoff, 3051 has a fascinating history. Toly ordered the car while visiting the Lamborghini stand at the 1965 Torino Motor Show, believing it to be just the seventh Miura order placed. Toly raced the car several times shortly after taking delivery in the summer of 1967, and also used it as his daily driver for several years.

Off the road since 1980, this 1967 Lamborghini Miura P400, affectionately known as ‘Topo’, is about to undergo a total restoration in the Team CJ Works.

The first owner of this special car was legendary racer, collector, raconteur, author and car guy extraordinaire, Toly Arutunoff. Mr. Arutunoff bought the car new in 1967 and immediately took it racing – because that’s the type of thing he did!

December, 2025

November, 2025

October, 2025

September, 2025

July, 2025

June, 2025

May, 2025

April, 2025

February, 2025

January, 2025

December, 2024

November, 2024

October, 2024

August, 2024

July, 2024

June, 2024

May, 2024

April, 2024

February, 2024

January, 2024